UniQube Gas Condensing SQ-BPSW

UniQube Gas Condensing SQ-BPSW

6 functions UniQube with integrated gas condensing boiler

The end-users of UniQube Gas Condensing technology will utilize the heat from the fuel virtually without loss, because of using latent condensing heat. It’s good for the environment because using less fuel means using fewer energy resources, lower CO2 emission and consequently It’s good for your wallet. Even more: the final user’s heating system will be supplied by free solar thermal energy too and all other UniQube properties: buffer function, hygienic hot water, hydraulic separator, thermal stratification.

DOUBLE A CLASS

A class energy efficiency boiler with over 90% thermal efficiency and A class energy efficiency UniQube

UP TO 107.5% THERMAL EFFICIENCY

Reached by condensing technology when operating at low-temperature conditions, utilising not only the heat generated by combustion but also the water vapour content

NATURAL GAS AND LPG

Both fuels can be used giving the final user a choice

SOLAR AND GAS CONDENSING

Technologies combined with enegy-saver UniQube tank are providing lowest bills for heating and hygienic hot water

BUFFER INTEGRATION

Provides less energy loss due to low start/stop cycles of the boiler

DIGITAL CONTROL

with optional remote control of the heat source, room thermostats, anti-freeze protection

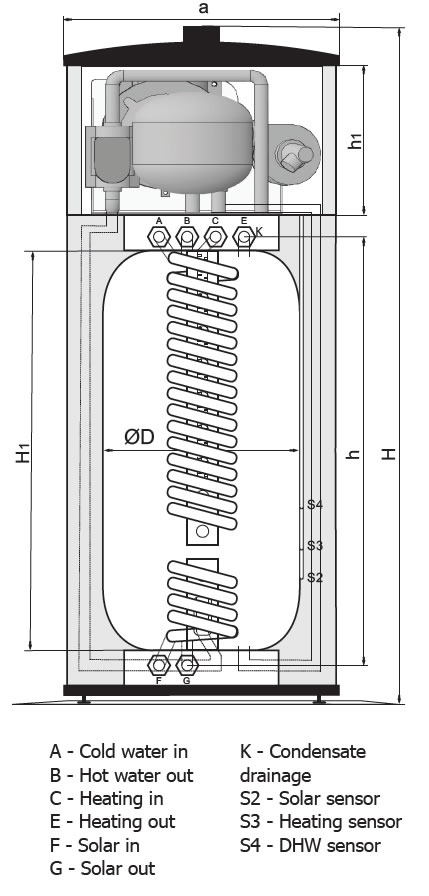

| UNIQUBE MODEL - SOLAR STORAGE TANK, DOMESTIC WATER HEATER, STRATIFIED SEPARATOR STORAGE TANK | ||

|---|---|---|

| TYPE SQ-BPSW | 310 | |

| D (diameter) | (mm) | 620 |

| H1 (height) | (mm) | 1300 |

| h (connectors) | (mm) | 1470 |

| Connections C, E | 5/4" | |

| H (height) | (mm) | 2000 |

| a (width) | (mm) | 734 |

| max. working temp. | (°C) | 90 |

| max. working pressure | (bar) | 3 |

| max. test pressure | (bar) | 4,5 |

| Net tank capacity | (l) | 290 |

| Approx. weight | (kg) | 119 |

| S2 Solar sensor position | (mm) | 1110 |

| S3 Heating sensor position | (mm) | 910 |

| S4 DHW sensor position | (mm) | 710 |

| Pivot measurement | (mm) | 1730 |

| Solar Heat Exchanger | ||

| Connections F, G | 5/4" | |

| max. working pressure | (bar) | 10 |

| max. test pressure | (bar) | 15 |

| capacity | (l) | 5 |

| output area | (m²) | 1,2 |

| Water Heat Exchanger | ||

| Connections A, B | 5/4" | |

| max. working pressure | (bar) | 10 |

| max. test pressure | (bar) | 15 |

| capacity | (l) | 15 |

| output area | (m²) | 3,8 |

| UNIQUBE GAS CONDENSING UNIT | ||

|---|---|---|

| TYPE GC | ||

| Gas Category | II2H3B/P | |

| Flue Type | C13(X), C33(X), C43(X), C53(X), C63(X), C83(X), B23, B33 | |

| Capacity-Efficiency | ||

| Heating power output (Thermal Power) (min – max) – 60/80°C | kW | 5,6 – 14,1 |

| Heating power output (Thermal Power) (min – max) - 30/50°C | kW | 6,7 – 15 |

| Heating power input (Thermal Load) (min – max) | kW | 6,2 – 14,5 |

| Efficiency (80°/60° C Max) | % | 97,5 |

| Efficiency (30°C Return) | % | 107,5 |

| Gas Consumption | ||

| Natural Gas (At Min-Max Power) | m³/h | 0,65 – 1,53 |

| Nox Class | 6 | |

| General | ||

| Power Supply | V AC-Hz | 230V 50Hz |

| Electric Consumption (Max-Standard Pump / Efficient Pump) | W | 120 / 60 |

| Protection Class | IPX4D | |

| Weight (Net) | kg | 28,5 |

| General | ||

| C02 ratio (min – max-G20) | % | (8,9 - 9,15) ± 0,2 |

Dedication of our expert team have already contributed the implementation of quality standards ISO 9001:2008 and certification of the UniQubes, by TUV Hessen, for complying with Pressure Equipment Directive